In the realm of engine maintenance and repair, precision and reliability are paramount. When it comes to servicing high-performance engines like those manufactured by Perkins, using the correct parts and documentation is critical. One of the essential resources for any technician working on Perkins engines is the factory Perkins parts book manual. This article delves into the importance of using this manual, highlights the key components for effective service work, provides a step-by-step guide to changing cams and pushrods, and discusses the advantages of relying on authentic Perkins parts.

Importance of Using the Factory Perkins Parts Book Manual

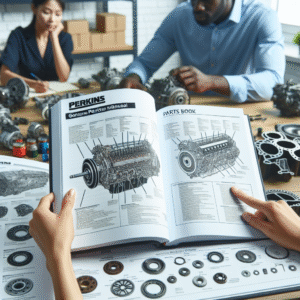

The factory Perkins parts book manual is an indispensable tool for anyone involved in servicing Perkins engines. It provides comprehensive details about the various components that make up the engine, ensuring that technicians have accurate information at their fingertips. This manual helps in identifying the correct parts, their specifications, and their placement within the engine, thereby reducing the risk of errors during maintenance.

One of the primary benefits of using the factory Perkins parts book manual is the assurance of compatibility. Engines are complex systems where each component must work in harmony with others. Using the wrong part can lead to suboptimal performance or even damage. The manual ensures that technicians select parts that are specifically designed for the engine in question, maintaining the integrity and performance of the engine.

Additionally, the factory Perkins parts book manual includes detailed illustrations and diagrams. These visual aids are incredibly useful for understanding the layout and assembly of the engine components. They provide a clear reference point, making it easier to carry out repairs and replacements accurately. This level of detail is especially valuable for complex tasks such as changing cams and pushrods.

The manual also offers valuable insights into the maintenance schedules and recommended practices for Perkins engines. It outlines the intervals at which various parts should be inspected, serviced, or replaced, helping to extend the lifespan of the engine. Following these guidelines ensures that the engine operates at peak efficiency and reduces the likelihood of unexpected breakdowns.

Moreover, the factory Perkins parts book manual is an authoritative source of information. It is produced by the manufacturer, ensuring that the content is accurate and up-to-date. Technicians can trust the information provided, knowing that it is based on the latest research and development from Perkins.

For those interested in accessing the factory Perkins parts book manual, it can be found at Perkins Manual. This resource is invaluable for anyone tasked with maintaining or repairing Perkins engines, providing all the necessary information to perform service work effectively and efficiently.

Key Components for Effective Service Work on Engines

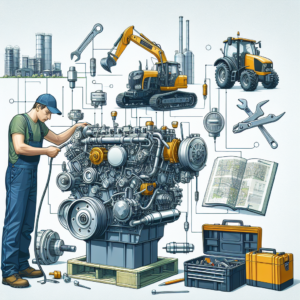

Effective service work on engines requires a thorough understanding of the key components involved. For Perkins engines, some of the critical parts include cams, pushrods, pistons, valves, and the crankshaft. Each of these components plays a vital role in the engine’s operation, and proper maintenance is crucial for ensuring optimal performance.

Cams are essential for controlling the timing and duration of the valve openings. They are responsible for the precise movement of the valves, which in turn affects the engine’s breathing and combustion efficiency. Regular inspection and replacement of cams are necessary to maintain the engine’s performance, especially in high-stress environments.

Pushrods are another vital component, acting as the intermediary between the camshaft and the valves. They transfer the motion from the camshaft to the valves, ensuring that they open and close at the correct times. Worn or damaged pushrods can lead to poor engine performance and increased wear on other components. Therefore, regular checks and replacements are crucial.

Pistons and valves are also integral to the engine’s operation. Pistons are responsible for converting the energy from fuel combustion into mechanical motion, while valves control the flow of air and fuel into the engine and the expulsion of exhaust gases. Keeping these components in good condition is essential for maintaining engine efficiency and power.

The crankshaft, which converts the linear motion of the pistons into rotational motion, is another key component. It is subject to significant stress and must be inspected regularly for signs of wear or damage. Proper maintenance of the crankshaft ensures smooth engine operation and reduces the risk of catastrophic failure.

In addition to these components, various seals, gaskets, and bearings play a crucial role in the engine’s performance. These smaller parts ensure that the engine operates smoothly and efficiently by preventing leaks and reducing friction. Regular inspection and replacement of these components are necessary to avoid minor issues that can lead to significant problems over time.

To ensure that all these components are properly maintained, technicians should refer to the factory Perkins parts book manual. This manual provides detailed information on each component, including specifications, installation instructions, and maintenance guidelines. Accessing this resource at Perkins Manual can significantly enhance the effectiveness of service work on Perkins engines.

Step-by-Step Guide to Changing Cams and Pushrods

Changing cams and pushrods in a Perkins engine is a task that requires precision and attention to detail. The following step-by-step guide outlines the process, helping technicians carry out this maintenance task effectively.

- Preparation: Begin by consulting the factory Perkins parts book manual to identify the correct parts and tools required for the job. Gather all necessary equipment, including the replacement cams and pushrods, gaskets, and any specialized tools. Ensure that the work area is clean and well-lit.

- Engine Disassembly: Start by disconnecting the battery and draining the engine oil. Remove any components that obstruct access to the camshaft and pushrods, such as the valve covers, intake manifold, and timing cover. Keep track of all removed parts and their respective positions.

- Camshaft Removal: Carefully remove the timing chain or belt, ensuring that the engine’s timing marks are aligned. Remove the camshaft retaining bolts and gently extract the camshaft from the engine. Inspect the camshaft for signs of wear or damage and compare it with the new camshaft from the factory Perkins parts book manual.

- Pushrod Removal: Next, remove the pushrods by carefully lifting them out of their guides. Inspect each pushrod for signs of wear, bending, or damage. Replace any pushrods that do not meet the specifications outlined in the factory Perkins parts book manual.

- Installation of New Components: Install the new camshaft by carefully aligning it with the timing marks and securing it with the retaining bolts. Apply assembly lube to the camshaft lobes as recommended in the manual. Next, insert the new pushrods into their guides, ensuring that they are correctly seated.

- Reassembly and Testing: Reassemble the engine by reinstalling the timing chain or belt, timing cover, intake manifold, and valve covers. Refill the engine with oil and reconnect the battery. Start the engine and check for proper operation, listening for any unusual noises that may indicate improper installation.

Throughout this process, the factory Perkins parts book manual is an invaluable resource. It provides detailed instructions and specifications for each step, ensuring that the job is done correctly. For more detailed information and access to the manual, visit Perkins Manual.

Advantages of Relying on Authentic Perkins Parts

Using authentic Perkins parts for engine maintenance and repair offers several significant advantages. These parts are designed and manufactured to meet the exact specifications of Perkins engines, ensuring optimal performance and longevity.

One of the primary advantages is reliability. Authentic Perkins parts are made from high-quality materials and undergo rigorous testing to ensure they meet the highest standards. This reliability translates to fewer breakdowns and reduced downtime, which is especially important for engines used in critical applications.

Another advantage is compatibility. Authentic Perkins parts are designed to work seamlessly with other components in the engine. This compatibility ensures that the engine operates efficiently and reduces the risk of damage caused by incompatible parts. The factory Perkins parts book manual provides detailed information on the correct parts for each engine model, making it easy to find the right components.

Using authentic Perkins parts also helps maintain the engine’s warranty. Many manufacturers require the use of genuine parts to keep the warranty valid. By using authentic Perkins parts, technicians can ensure that any warranty claims are honored, providing peace of mind to the engine owner.

Furthermore, authentic Perkins parts often come with support and service from the manufacturer. This support can include technical assistance, troubleshooting, and access to updated documentation. Technicians can benefit from this support, ensuring that they have the information and resources needed to perform maintenance and repairs effectively.

Cost-effectiveness is another advantage of using authentic Perkins parts. While genuine parts may have a higher initial cost compared to aftermarket alternatives, they often provide better value in the long run. Their durability and reliability mean fewer replacements and repairs, ultimately saving money over the engine’s lifespan.

Finally, using authentic Perkins parts contributes to the overall performance and efficiency of the engine. These parts are engineered to work together, ensuring that the engine delivers the power, fuel efficiency, and emissions performance that Perkins engines are known for. Accessing these parts through the factory Perkins parts book manual, available at Perkins Manual, ensures that technicians have the best components for maintaining and repairing Perkins engines.

In conclusion, the factory Perkins parts book manual is an essential resource for anyone involved in the maintenance and repair of Perkins engines. It provides detailed information on the correct parts and procedures, ensuring that service work is carried out effectively and accurately. By understanding the importance of using this manual, familiarizing oneself with key engine components, following a step-by-step guide for tasks like changing cams and pushrods, and relying on authentic Perkins parts, technicians can ensure the reliability and performance of Perkins engines. For more information and access to the factory Perkins parts book manual, visit Perkins Manual.